Pumps, Compressors, Valves

Purpose: With the availability of high-quality resin 3D printing, creating a mold for sand casting a part is a practical approach. Many components in turbochargers are manufactured using sand casting, including the compressor cover, turbine, and bearing housings. The parts shown below were modeled, and a CFD solution was obtained (without specific design parameters):

Volute:

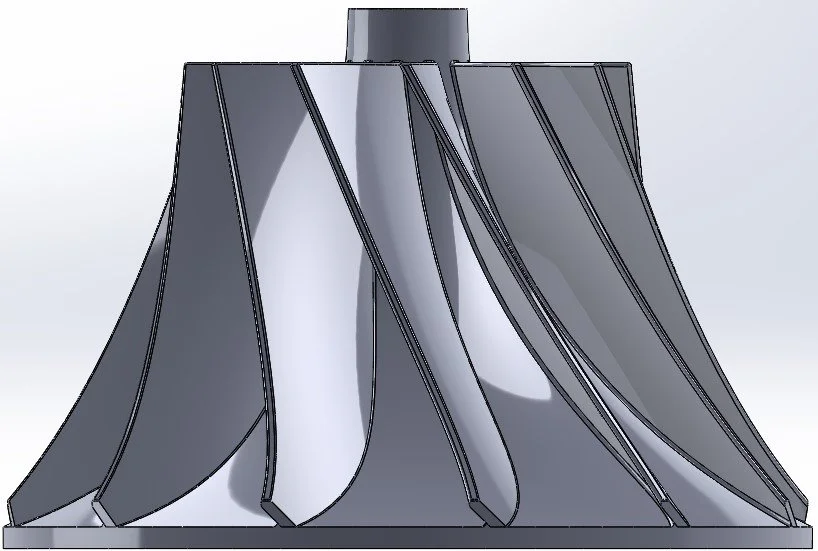

Compressor wheel:

Assembly [Compressor stage]:

Using water as the working fluid, an issue with the pressure outlet was observed within approximately five minutes. The simulation was allowed to complete.

Chose the wrong direction for my rotating region. I changed the direction and reran it. Mistakes happen.

The results have improved, and the behavior of the pressure outlet is becoming clearer.

The cut plot clearly shows that velocity reaches a maximum where pressure is at a minimum. This observation aligns with Bernoulli’s equation, which describes an inverse relationship between pressure and velocity.